ULTRASONIC THICKNESS GAUGE AI-H001IntroductionUltrasonic Thickness Gauge measuring with ultrasonic wave is applicable for measuring the thickness of any material in which ultrasonic wave can be transmitted and reflected back from the other face. The gauge can provide quick and accurate measurement to various work pieces such as sheets of board and processing parts. Another important application of the gauge is to monitor various pipes and pressure vessels in production equipment, and monitor the thinning degree during using. It can be widely used in petroleum, chemical, metallurgy, shipping, aerospace, aviation and other fields. 1.1 Technical Specification

Other Size and Type Available on Request. |

|

AI-10 High-Precision ULTRASONIC Thickness Gauge• Ultrasonic Thickness Gauges are designed to improve safety and ensure reliability of material subject to corrosion or erosion. • Corrosion gauges with their dual-element transducers are the primary inspection tool used to measure the remaining walls of components such as pipelines, pressure vessels, storage tanks, and numerous other applications.. • Precision gauges use single-element transducers to provide the thinnest range and highest degree of accuracy possible. Common applications include metals and a variety of non-metals (i.e. glass, ceramic, plastic, etc.) Specifications:

Standard Delivery: Main Unit,, TWO test Probes, Data Cable, Software, Coupling oil, Battery, Operation Manual, Carrying case.Other Sizes and Types Available on Request. |

|

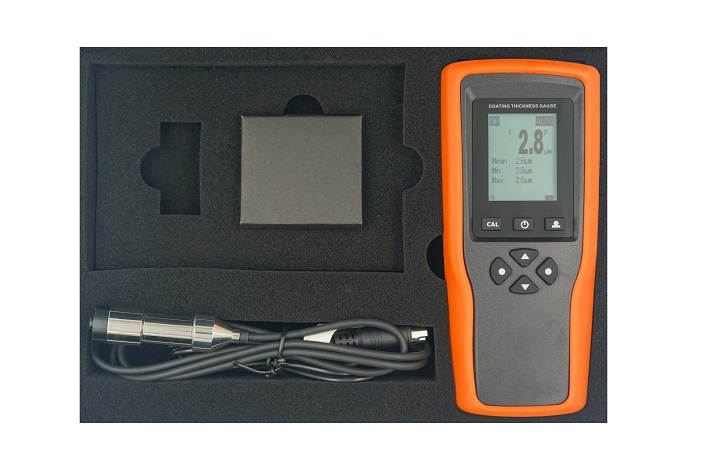

COATING THICKNESS GAUGEHigh Accuracy And Wide Range Coating Thickness Gauge With Separated Probe PG-CTG-100 Product Description:The measuring range of this coating thickness gauge is up to 5000um. It is used for non-destructive coating thickness measurement of nonmagnetic coatings on steel and insulating coatings on non-ferrous metals. It is with separated external probe and can be replaced easily.

Specifications:

|

|